Model No.︰HZ1010C

Brand Name︰HarmonyWOLRD/OEM/ODM

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

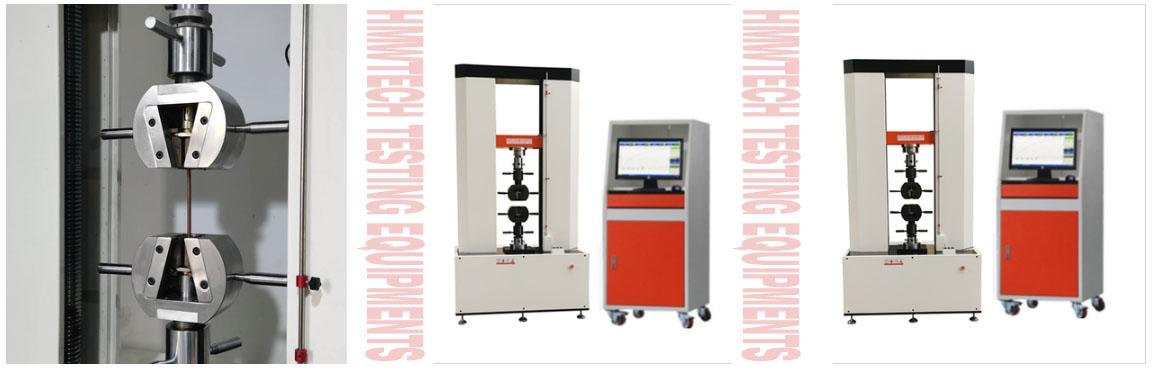

Computer-based servo-type universal material testing machine (large deformation) This machine adopts electromechanical integration design, mainly composed of force-measuring sensor, transmitter, microprocessor, load driving mechanism, computer and color inkjet printer. It has a wide and accurate loading speed and force measuring range, high accuracy and sensitivity for the measurement and control of load and displacement, and can also carry out automatic control tests of constant speed loading and displacement. The floor-type model and the modeling and painting have fully considered the relevant principles of modern industrial design and ergonomics.

Purpose of universal material testing machine:

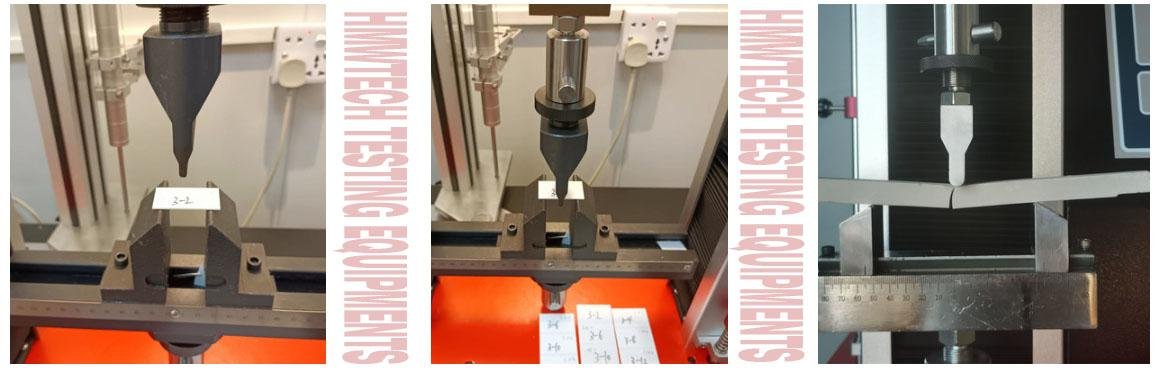

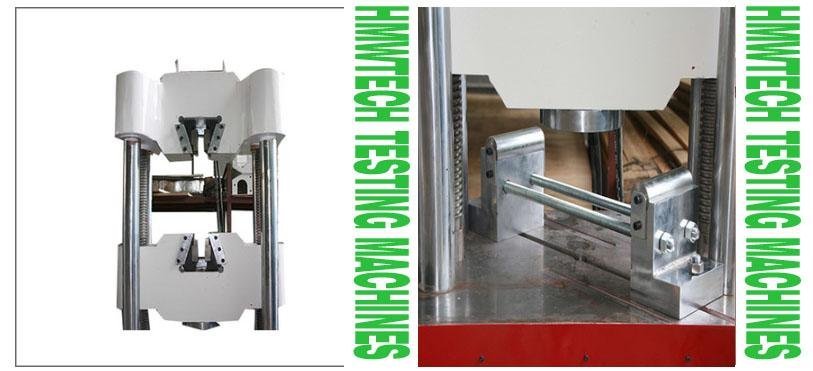

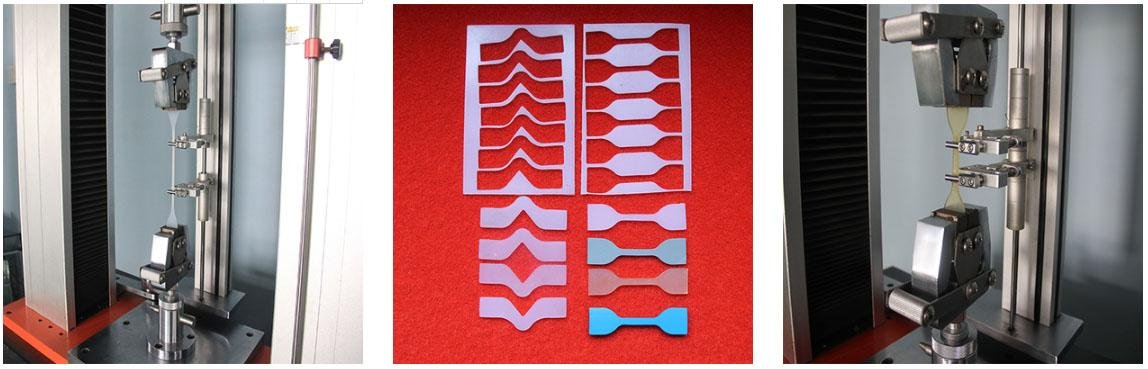

HZ-1010C computerized servo universal material testing machine (large deformation) This testing machine is applicable to flexible materials with large deformation such as rubber and plastic. It can complete tensile, tear, adhesive strength, peeling and other tests. It is equipped with a large deformation extensometer for measuring specimen deformation, which is suitable for testing the mechanical properties of materials with large deformation.

Industry of universal material testing machine application:

HZ-1010C computer-based servo universal material testing machine (large deformation) is widely used in measurement and quality inspection; Rubber and plastic; Textile chemical fiber; Wire and cable; Packaging materials and food; Instruments and Apparatuses; medical apparatus and instruments; Civil nuclear energy; Civil aviation; Colleges and universities; Research Institute; Commodity inspection, arbitration and technical supervision departments; Building materials ceramics; Application of force value and elongation to be measured in petrochemical industry.

Maximum load

100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN, optional within

Accuracy class

Level 1/0.5

Effective force measuring range

0.2%~100% (level 1)/0.4%~100% (level 0.5)

Force measuring accuracy

Within ± 1% of the indicated value/within ± 0.5% of the indicated value

Resolution of testing machine

The maximum load is 1/200000, the internal and external gears are not divided, and the resolution of the whole process is unchanged

Load cell

Basic configuration: one tension and pressure sensor (maximum load)

Extended configuration: multiple sensors can be added

Effective test width

450mm (can be widened according to customer requirements)

Effectively extrude space

400, 500, 600mm (can be increased according to customer requirements)

Test speed range

0.001~500mm/min

Displacement measurement accuracy

Within ± 0.5% of the indicated value/within ± 0.2% of the indicated value

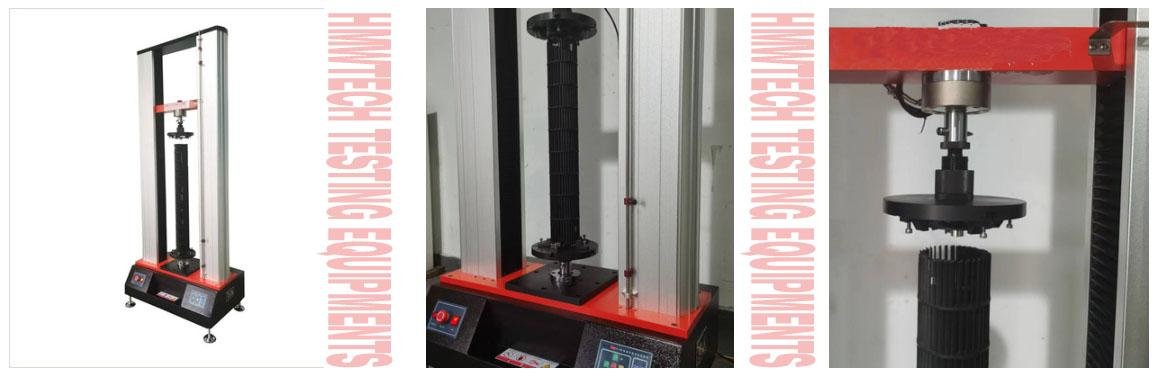

Deformation measuring system

(Optional according to demand)

Basic configuration: large deformation: minimum gauge distance 10mm, deformation range: 800mm

Extended configuration: small deformation: gauge length 25mm, 50mm, 100mm deformation range: 5mm, 10mm, 25mm

Deformation measurement accuracy

Within ± 0.5% of the indicated value (large deformation or small deformation can be selected according to customer requirements)

Overload protection

If the maximum load exceeds 10%, the machine will automatically protect

Fixture configuration

One set of stretching fixture

Host size

1200 * 530 * 1800mm (L * W * H)

dynamic system

Taiwan Delta AC servo motor+drive+high-precision ball screw

Power Supply

220V、50HZ、

power

0.75KW (different power motors are equipped as standard according to different force values)

Weight of main engine

(About) 500 Kg